Industrial Coffee Mill Guide: Increase Efficiency and Quality

In the competitive landscape of coffee manufacturing, choosing the appropriate industrial coffee mill plays a crucial duty in improving both performance and product quality. Understanding the nuances of different grinder kinds and crucial features-- such as customizable grind settings and durable building-- can significantly influence the final taste account of the coffee.

Understanding Mill Types

When picking an industrial coffee grinder, recognizing the various types readily available is vital for maximizing both taste removal and operational performance. The 2 key types of mills are blade mills and burr mills.

Ultimately, choosing the ideal sort of mill is important to keeping high quality and effectiveness in coffee manufacturing, making it necessary for services to purchase top quality burr grinders for optimum outcomes.

Trick Attributes to Take Into Consideration

Picking a commercial coffee mill calls for careful consideration of numerous key functions that can dramatically influence both performance and the overall coffee experience. One of the main aspects to assess is the grinding system. Burr mills are typically liked over blade grinders, as they supply a consistent work size, which is vital for optimum extraction and flavor.

An additional essential feature is the grinder's capability. A flexible mill with several settings allows you to customize the grind dimension to various brewing approaches, boosting the coffee's taste profile.

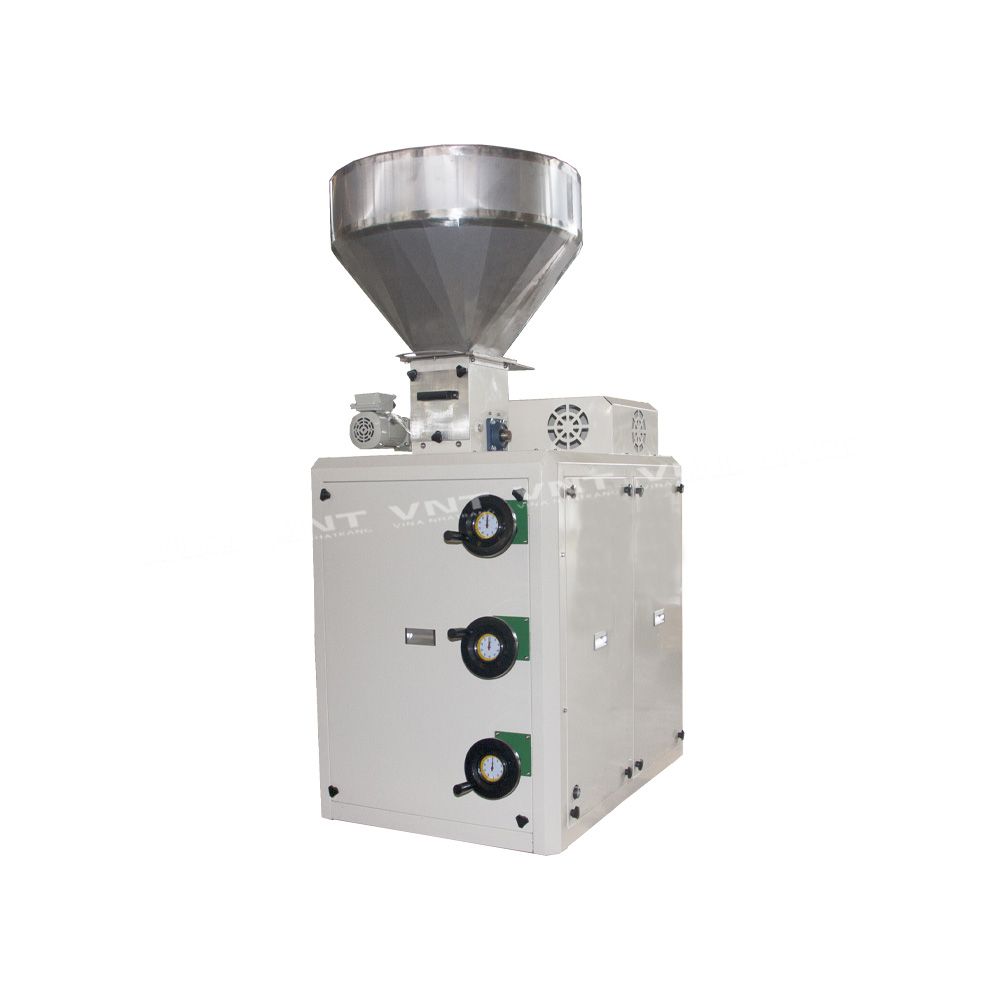

The building material additionally plays a function in toughness and maintenance. Stainless steel parts frequently offer longevity and are simpler to clean, which is essential for maintaining health requirements. Lastly, evaluate the grinder's noise degree, particularly in a hectic coffee shop or manufacturing setting, where too much noise can be disruptive. Buying a grinder that stabilizes these attributes can considerably enhance both functional performance and the quality of the coffee offered.

Optimizing Grinding Process

To accomplish the most effective outcomes in coffee prep work, optimizing the grinding process is crucial. The work dimension dramatically affects extraction, flavor, and total top quality of the made coffee. Different brewing methods call for certain work sizes; for instance, coffee requires a fine grind, while French press requires a coarse appearance. Understanding the partnership between work size and brewing approach is the initial action in optimization.

Additionally, checking the grinding speed can enhance the process. Slower grinding commonly produces much less warmth, preserving delicate tastes and fragrances. Conversely, quicker grinding might create too much warm, negatively impacting the coffee's top quality.

Maintenance and Treatment Tips

Proper maintenance and care of commercial coffee mills are important for making sure optimum performance and long life. Regular cleaning is the foundation of upkeep; deposit build-up can influence flavor and grinding effectiveness. It is a good idea to clean up the grinder after each usage, wiping down the exterior and site here eliminating any coffee grounds from the burrs.

Additionally, examine the grinding burrs for wear and tear. Dull burrs can compromise work consistency, so they ought to be changed as essential. Industrial Coffee Grinder. Regularly calibrating the grinder is likewise crucial, as this keeps the preferred work dimension for different brewing approaches

Lubrication of moving components should be done according to the maker's specs, as this lowers friction and extends the life of the tools. It is vital to use food-grade lubes to ensure security and compliance with wellness guidelines.

Lastly, keep the grinder in a steady and completely dry setting to stop corrosion and rust. By sticking to these maintenance and treatment suggestions, operators can improve the efficiency of their commercial coffee grinders while guaranteeing top notch result and prolonged functional life.

Return on Investment Evaluation

Evaluating the return on financial investment (ROI) for my latest blog post commercial coffee mills is critical for organizations seeking to maximize their coffee production capabilities. A comprehensive ROI evaluation helps identify the financial feasibility of spending in premium mills, permitting services to weigh the initial costs against potential gains.

Analyze the purchase rate of the mill, including installment and any kind of necessary alterations to existing framework. YOURURL.com High-performance mills typically lead to minimized grinding time and enhanced throughput, which can considerably improve productivity.

In addition, take into consideration the influence on product high quality. Industrial Coffee Grinder. Superior grinders yield an even more regular work size, which can improve flavor accounts and customer satisfaction, ultimately driving sales. By increasing the high quality of the last product, services can justify higher rates, resulting in raised earnings

Final Thought

In recap, a commercial coffee grinder plays a crucial duty in enhancing both efficiency and item quality within coffee production. By choosing top quality burr mills furnished with crucial features such as flexible grind setups and durable building, services can make sure optimal flavor extraction. Additionally, regular maintenance is vital for sustaining mill performance and making the most of client fulfillment. Ultimately, the calculated investment in a reliable grinder contributes dramatically to improved revenue and competition in the coffee sector.

In the affordable landscape of coffee production, picking the ideal industrial coffee grinder plays an essential duty in enhancing both efficiency and item top quality. The two main kinds of mills are blade mills and burr mills. Within the burr mill group, there are level burr mills and cone-shaped burr mills, each with its benefits. Burr grinders are typically preferred over blade mills, as they offer a consistent work dimension, which is essential for optimum extraction and taste.

In summary, an industrial coffee mill plays a crucial duty in improving both performance and item high quality within coffee production.